AMES GROUP SINTERING SA

SUBFORNITURA MECCANICA

Find us at MECSPE 2026

25

C74

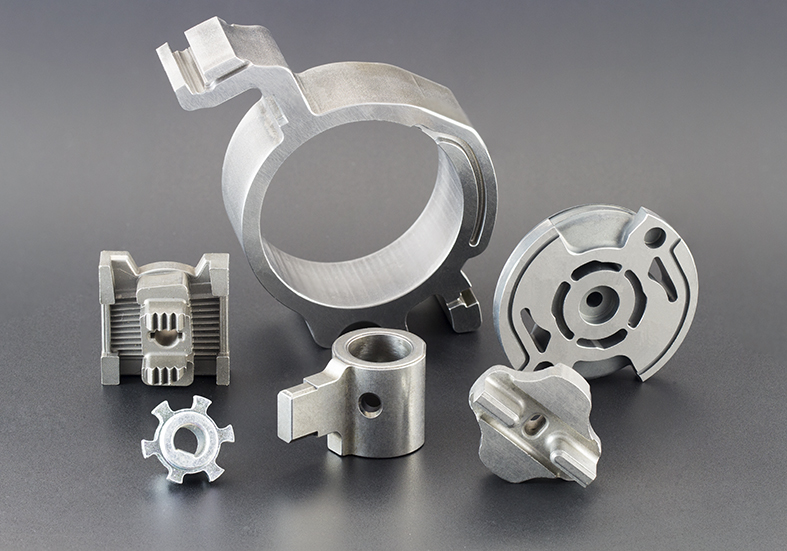

Sintered steel metallic components

Pav. 25 Stand C48

Advantages:

Powder metallurgy makes it possible to obtain high-performance parts from a wide variety of steels (including stainless steel), forming processes and sintering technologies, complemented with heat treatments, mechanical treatments, coatings and various types of finishings. Their mechanical properties are comparable to those of wrought structural steels or alloyed cast iron, reaching a tensile strength greater than 1,300 MPa.

Application Sectors:

The powder metal components present inside cars are in engines, transmissions, transfer cases, exhaust, starters, brakes, steering, shock absorbers, comfort and safety systems (rear-view mirrors, seats, sunroofs, HVAC) and various pumps (oil, fuel, water, servobrake, SCR, VVT, CVT).

A large number of steel components for mechanical and hydraulic use are produced by Powder Metallurgy. They are, in general, parts with complex geometry and high dimensional precision, which offer great reliability and repeatability in large series.