SME innovation thanks to PNRR funds

MECSPE, a reference for upgrading enterprises in the field of technology

Many special initiatives dedicated to education, an asset on which the exhibition itinerary is developed along with digitization and sustainability

Milan, Oct. xx 2022 – With a GDP of +3.2 percent, according to the latest government estimates, and the latest data on industry turnover, which grew in July in trend by +16.3 percent (Istat), manufacturing is confirmed as the country’s driving force, despite the difficulties due to inflation and high energy prices that the Italian business network has been facing in recent months. A sector that can count on PNRR funds (13.4 billion euros) earmarked for the Transition 4.0 to pursue the goal of digital transformation. In fact, the MISE has already given access to tax credits during 2022 aimed at incentivizing private investment in innovation.

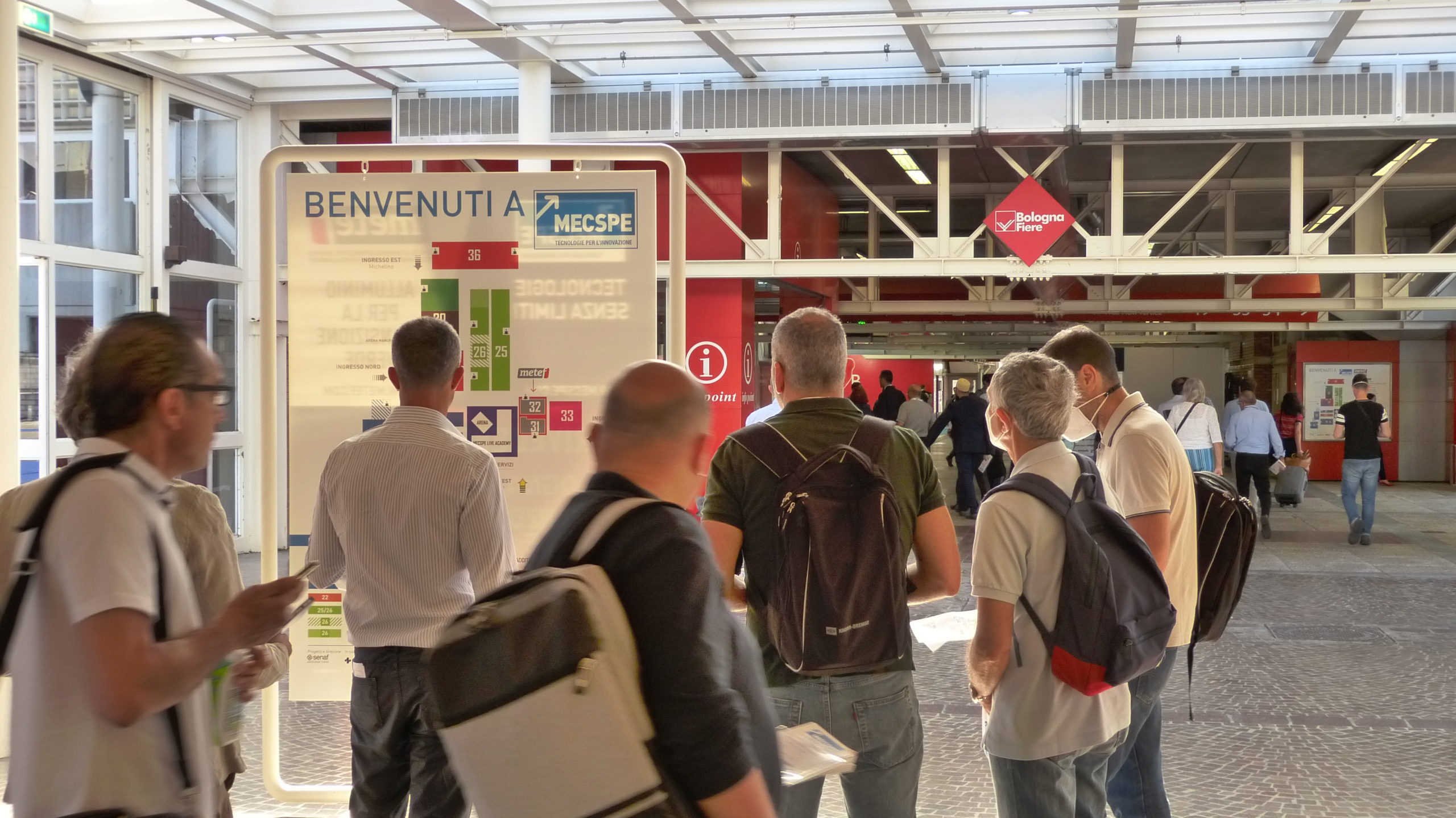

What are the results? Organized by Senaf, MECSPE is the most important trade show in Italy dedicated to manufacturing and technological innovation and is scheduled for March 29-31, 2023 at BolognaFiere. MECSPE questioned a number of industry associations, the results of the incentives are positive with many companies having already taken advantage of them.

For Roberta Piccinini, president of the Mechanics CNA (National Confederation of Crafts and SMEs): “CNA members with small businesses in the mechanical sector have benefited from the measure in a major way. The investments made involved, in most cases, more high-performance and interconnected machinery, robots, and software for integrated business management. We believe this is undoubtedly a very important measure to enable our companies to equip themselves and make the technological leap needed to remain competitive in international markets. I also believe that it would be appropriate to make it structural and not drop the percentage of aid, as is unfortunately planned for the coming years.

For Federico Boin, national president of Confartigianato Meccanica (labor organization of the mechanical craft sector): “The incentive referred to is the result of the evolution over time of other forms of relief known as ‘hyper depreciation.’ And while the latter – when it was introduced – mostly attracted the attention of industry, its natural evolution into what is now called the 4.0 transition tax credit has been and is being used by a very large number of companies, including “micro” ones. Having streamlined the bureaucratic process of obtaining and using the tax credit, it can be said that the facility is now also known by activities that – by definition – are predominantly manual, such as hairstylists or construction companies. In fact, lasers to perform treatments, cranes and mechanical arms equipped with particularly sophisticated and innovative digital components, make credit usable not only to categories of craftsmen, so to speak, engaged in mass production. The disappearance from next year of traditional incentives for the purchase of capital goods (read maxi or super depreciation, then also converted into tax credits) is prompting businesses to look even more closely at the 40 percent tax credit for 4.0 investments. Of course, there are possible areas for improvement, for example, regarding the extension of the tax credit for staff training on the use of these new technologies for future years as well, or the enhancement of the so-called “Nuova Sabatini” (a government subsidy to facilitate access to credit for businesses and increase the competitiveness of Italy’s production system) in conjunction with the tax credit being discussed.”

In the same vein is Leonardo Iezzi, Executive Director of Apindustria Brescia “From the data in our possession, the measure has been widely used. The incentive in place is certainly of interest to companies, but it should be pointed out, however, that it would be essential to maintain, even for next year, the percentages currently in place.”

For Maruska Sabato, Project Manager of MECSPE,“MECSPE is the hub for updating skills and integrating the latest innovations in companies. In this sense, our goal is precisely to foster dialog among all industry players with our eyes on the future of our industrial network. The latest measures arranged by the government have given a boost to this process, which has already been underway since the introduction of Industry 4.0 funds, which thanks to the NRP continue to be available to entrepreneurs.”

The issue of innovation is therefore a priority challenge for businesses to grow and look to the future with optimism. Furthermore, it is one of the goals of MECSPE, which will also in its 21st edition be concerned with fostering the meeting and technological development of companies, with an increasingly rich program of in-depth studies and special initiatives dedicated to digitization, training and sustainability, the three fundamental assets for growth in 4.0.

As MECSPE Observatory data show, 42 percent of companies have made investments in the digital field, demonstrating significant growth in this regard following the pandemic: this is +15 percent compared to the same period in 2021. When we talk about digital investment, what are businesses focusing on? Mainly they turned to cybersecurity (43 percent), followed by collaborative robotics (26 percent) and cloud computing (25 percent).

Taking place concurrently to MECSPE will be METEF, the international expo dedicated to Senaf’s aluminum supply chain, a sector central to sustainable industrial production. Finally, in 2023, MECSPE will double its date and will also be held in Bari from November 23rd to 25th with “Focus Mediterraneo” at the Nuova Fiera del Levante, with an edition dedicated to the development of 4.0 technologies and a proposal increasingly focused on sustainability and innovation of production processes.

The numbers of MECSPE 2022

39,348 trade visitors, 92,000 square meters of exhibition space, 2,000 companies, 2,000 square meters of the Cuore Mostra MECSPE LIVE ACADEMY, along with 16 special initiatives and conferences.

MECSPE Exhibitions

Machines and Tools – Machine tools, Equipment, Tools and Design Software; Machines, Materials and Sheet Metal Working – Bending, Stamping, Cutting, Assembly, Welding, Materials and Software; Digital Factory – Industrial Informatics, IoT, Industrial Sensing, Cloud – manufacturing, Automatic Identification Technologies, Applications, Devices, Instrumentation and Intelligent Components for Process Interpretation and Interconnection; Logistics – Packaging, Packing, Handling, Material handling, Lean manufacturing, Warehouse management software, Supply chain management, Safety systems, PPE, Outsourcing; Mechanical Subcontracting – Precision mechanical processing, Metal carpentry, Mechanical construction, Fasteners, Foundries, Small parts, Wire processing, Contract industrial processing, Micromachining; Electronic subcontracting – Cem (contract electronics manufacturer), Wiring harnesses, Ems (electronics manufacturing service), PCB (printed circuit board manufacturers), Engineering and design offices; Eurostampi, Machines and plastic, rubber and composites subcontracting – Plastics, rubber and composites processing, Machines and plants, Auxiliary equipment, Innovative materials, Molding, Extrusion, Packaging, Blowing, Molds, Models, Standardized components for molds, Design, Simulation and design software, Micromachining; Additive Manufacturing – 3D printing, Rapid prototyping, Rapid Manufacturing, Systems and services for reverse engineering, Additive technology, Materials, Services, Hardware: 3D printers and scanners, accessories, Simulation and design software; Treatments and Finishes – Surface Treatment Plants, Furnaces, Electroplating, Chemical and Electronic Processes, Washing, Metallization, Enameling, Galvanizing, Products and accessories for treatments, Heat Treatments, Painting; Non-Ferrous Materials and Alloys – Processing of non-ferrous materials (Aluminum, Titanium, Magnesium, Light Alloys), Die Castings, Foundries, Contract Industrial Processing, Technologies, Design, Engineering; Automation and Robotics – Automation and Robotics, Assembly, Assembly and Handling; Control and Quality – Certification and quality control, Metrology, Measuring instruments, Laboratory testing, Calibration, Analytical equipment, Vision; Power Drive – Mechanical power transmission devices, Hydraulics, Pneumatics, Mechatronics, Motion control, Maintenance, Compressed air.

For more information visit www.mecspe.com.

For further information

Press Office

MY PR – www.mypr.it

Roberto Grattagliano – cell 338 9291793 e-mail roberto.grattagliano@mypr.it

Caterina Conserva – cell 3401409543 e-mail caterina.conserva@mypr.it

Stefania Bonetti – cell 340 2513708 e-mail stefania.bonetti@mypr.it